- Markets & Applications

- Electronics

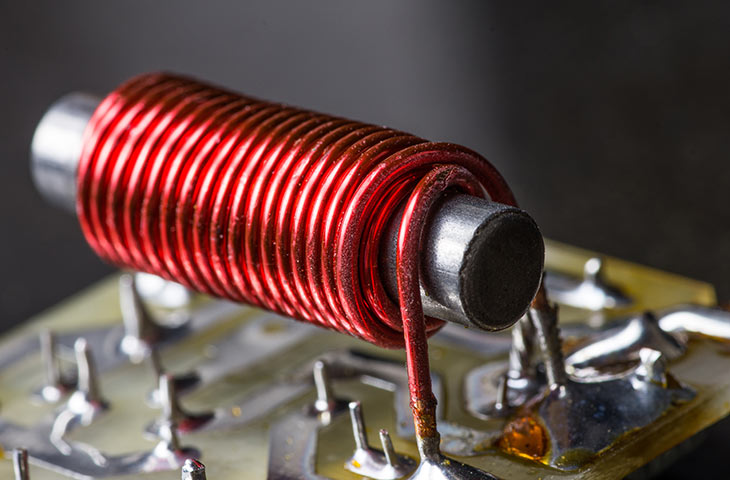

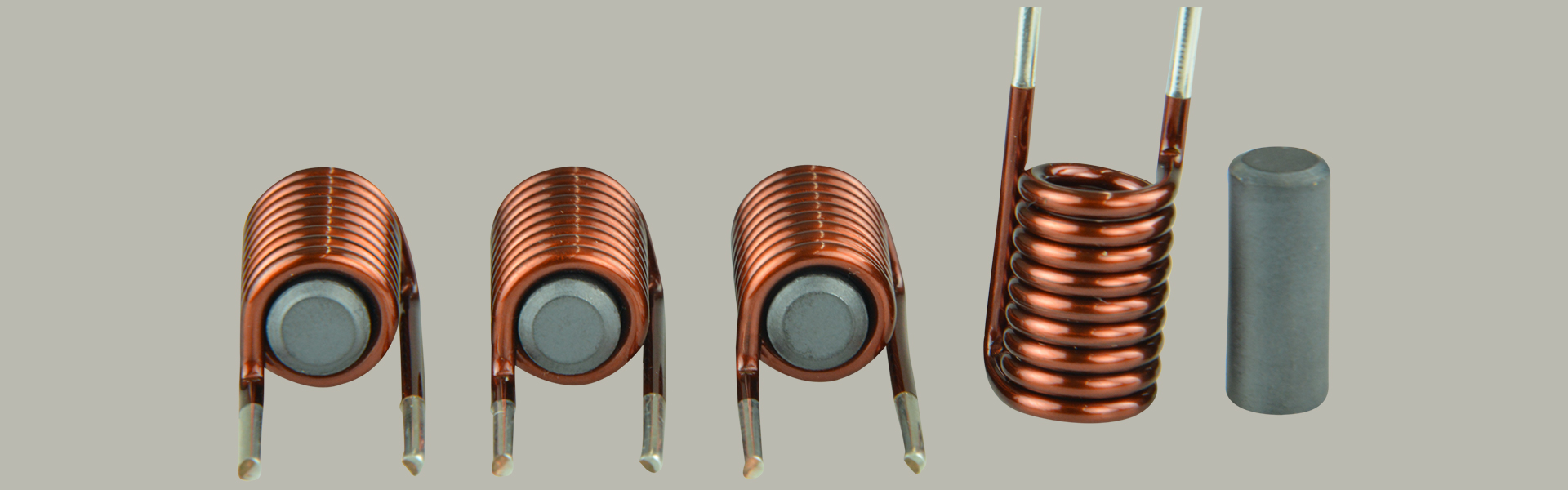

- Fixing and securing of ferrites in rod core chokes

Fixing and securing of ferrites in rod core chokes

Rod core chokes are being used as passive components (anti-interference coils) a hundred million times where electric interfering impulses need to be eliminated. This high amount of pieces demands a high speed production line and as a consequence fast curing adhesives. In the past , cyanoacrylates (instant adhesives) were used but they often could not meet the high thermal demands. The adhesive must fix the ferrite in the air coil - secure and vibration proof. For this specific application Kisling offers the fast curing two component adhesive system 1470/1471. These products passed long-term tests up to 180°C successfully and their flow characteristics ensure a self mixture when adhesive and activator are being dosed on the air gap between coil and core. Additionally, Kisling's 1470/1471 has a high chemical resistance.

- Fast curing, good temperature resistance, more energy-efficient compared to epoxies

- Fast curing independently of air humidity and therefore high process safety compared to instant adhesives (cyanoacrylates)

- Very low viscosity even in the case of temperature changes

- Excellent capillary flow characteristics

- Constant flow characteristics ensures adequate mixing - adhesives secures 60% of the coil length

- One product for different diameters

- Mixing ratio between 10:8 and 8:10 (w:w) are possible without significant changes of curing times or mechanical properties. Possible deviations are balanced in the dosing system