- Kisling

- New in the Kisling product range: Epoxy Encapsulants

New in the Kisling product range: Epoxy Encapsulants

Kisling expands its product range of potting compounds by four new smashing Epoxy Encapsulants

Following the successful integration of Copaltec and its polyurethane potting compounds in 2022, Swiss adhesives and sealants specialist Kisling is expanding its encapsulants range with four new epoxy encapsulants. With this expansion, Kisling is sharpening its focus on the growth markets of e-mobility and (power) electronics and is responding to the constantly increasing requirements in these areas. Both electronic components and electric motors are subject to ever-increasing demands in terms of service life, resilience and efficiency. The new encapsulants are intended to support customers in continuing to meet the demands of the market without any problems and to be able to obtain their potting solutions from a single source. The newly developed encapsulants comply with the REACH and RoHS directives and thus contribute to the protection of the user - he does not even have to worry about halogenated additives or SVHC substances either.

Thermally conductive systems for high heat dissipation applications

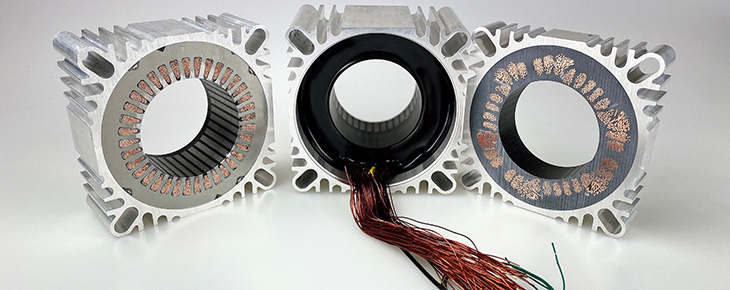

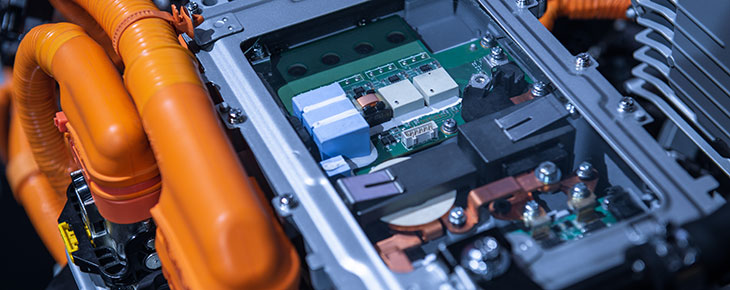

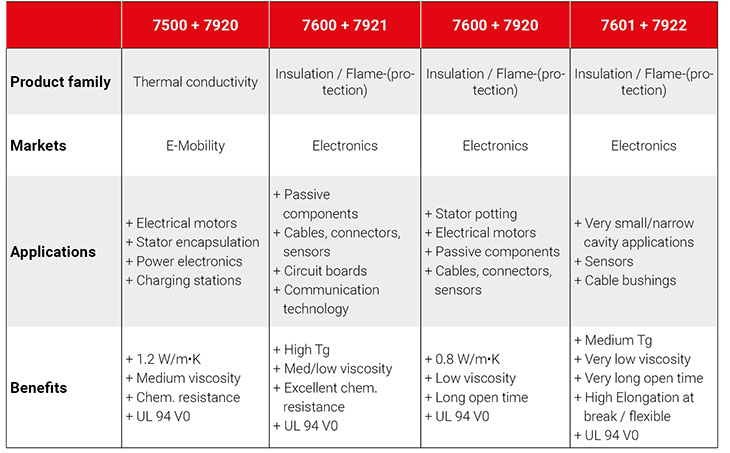

In the e-mobility sector, the product 7500+7920 with its thermal conductivity of 1.2 W/m-K contributes to increased efficiency through improved heat dissipation. The encapsulant is particularly suitable for applications in which high heat development occurs due to constantly increasing power densities in a small space.These include electric motors, charging stations and various power electronics components. By moderately increasing the processing temperature to 60 °C, the viscosity can be reduced to below 1000 mPas to ensure complete impregnation even in small cavities and narrow gaps.

In comparison, the 7600+7920 system offers a further reduced viscosity (down to ~300 mPas at 60 °C) and a significantly longer processing time. This is particularly advantageous in large-volume potting applications such as stators with moderate heat generation or where particularly good impregnation behaviour is required.

Images: Encapsulation of an electric motor and power electronics (converter, inverter, etc.) for improved heat dissipation and thus holistic efficiency enhancement

Insulating and flame retardant systems for electronics applications

The encapsulation resins 7600 and 7601 with the hardeners 7921 and 7922 are primarily designed for use in electronics encapsulation and can be used in three combinations.

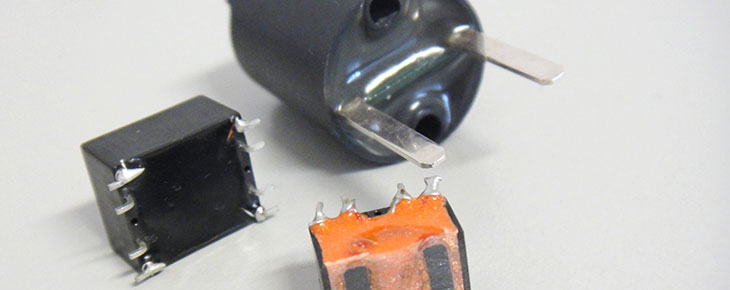

The encapsulation resin 7600+7921 offers a high glass transition temperature of ~95°C and a hardness of approx. 90 Shore D, providing very robust and chemically resistant protection for a wide range of electronic components. The flame-retardant properties according to UL 94 V0 at 4mm layer thickness ensure corresponding safety.

7601+7922, with an average glass transition temperature of approx. 40 °C and a reduced hardness of approx. 63 Shore D, offers a softer potting compound for large-volume applications where the potted components are sensitive to damage due to differences in the thermal expansion of the different materials.

The very low viscosity at room temperature cure of ~670 mPas (reducible down to ~140 mPas at 60 °C processing temperature) and the long processing time ensures reliable impregnation of very small cavities and narrow gaps. Both combinations achieve a thermal conductivity of 0.8 W/m-K and are thus also able to regulate moderate heat developments.

Images: Protection and electrical insulation of passive components and printed circuit boards against external influences

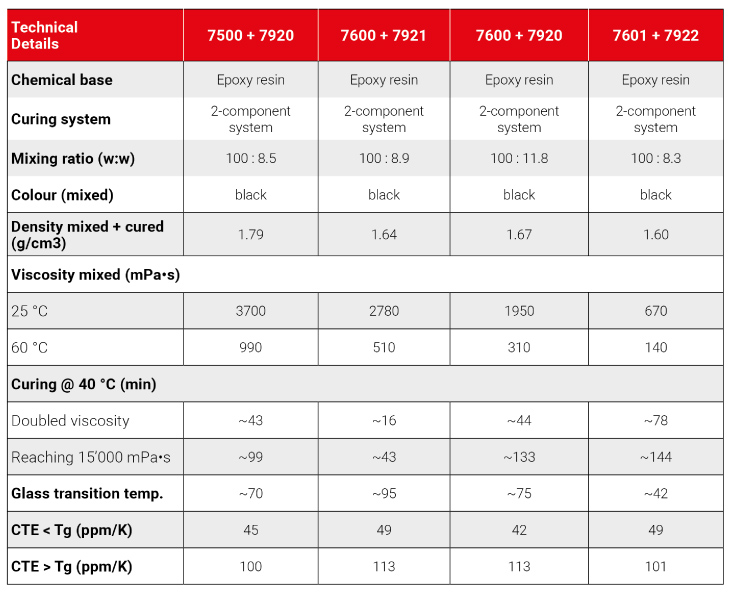

Summary table

Technical Data